There are numerous types of roller compactors that are available in rental markets that make it important for contractors to understand the different features of roller compactors in order to achieve optimal compaction. From smooth drum rollers to double drum rollers all the way to pneumatic rollers and vibratory rollers; each type of roller is designed to compact specific types of ground material.

In some instances, two different types of rollers are applied in order to achieve the desired level of compaction. In general, rollers may be categorised into 6 basic types (however some latest roller compactor models that are also available for hire may be equipped with two or more features), these are cylindrical, pneumatic, grid, vibratory and smooth-wheeled compactors. This article will examine each type in brief.

Cylindrical Roller Compactors

Cylindrical compactors are generally walk-behind rollers that are mostly used for compaction projects that do not cover large areas. These are lightweight compactors that allow a single person to push the roller over surfaces targeted for compaction. Generally, they are used for paving projects due to their small sizes.

Pneumatic Roller Compactors

These rollers can be ridden on and are fitted with pneumatic tires that allow the compactor to move over uneven terrain smoothly. The tyres of pneumatic roller compactors cover a large space and due to this a single operator may be able to perform large-scale compaction tasks quite quickly. These rollers are mostly used for compacting loose soil, or ground that consists of soft base course materials.

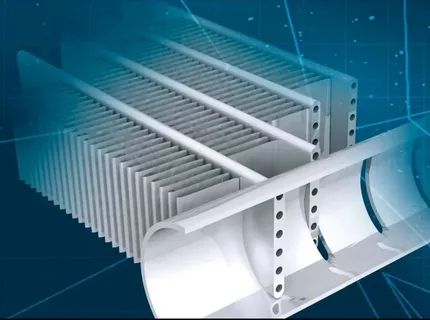

Grid Rollers

Grid roller compactors are fitted with steel bars on the drum in the shape of a grid that applies intense weight (high-contact pressure) to the surfaces being compacted. In some instances, contractors tend to add concrete blocks or different types of steel attachments in order to increase weight. This machine is generally suited for compaction of coarse soil for low-traffic roads.

Vibratory Rollers

Among the more popular among rollers that top the roller hire list are vibratory rollers that come in either single or double drum variants. These rollers are effective in compaction of most types of materials, but work best on granular bases such as gravel, crushed rock, and asphaltic concrete. These machines also come in various sizes that range from large to walk-behind machines that are mostly used for compacting smaller surface areas or congested project sites.

Smooth-wheeled or static rollers

A little similar to vibratory rollers in terms of design, these rollers may be fitted with either a single drum or double drums. In essence the single drummed versions are smaller in size and typically used for projects that are congested or confined. In most case scenarios, the single drum rollers are used for building sidewalks or paving highways.

In contrast, the double-drum rollers come with two rollers working in tandem and are generally bigger. The double drums are capable of compacting faster and cover wider areas compared to the single drum versions.