How is concrete produced? Its asked by many. Here, it is;

The concrete process consists of equipment’s which uses extensively, from hand tools to heavy industrial machinery. Whichever equipment builder’s practice, however, the aim is to supply the required building material; elements must mixed, placed, shaped, and retained within time constraints.

How is concrete produced?

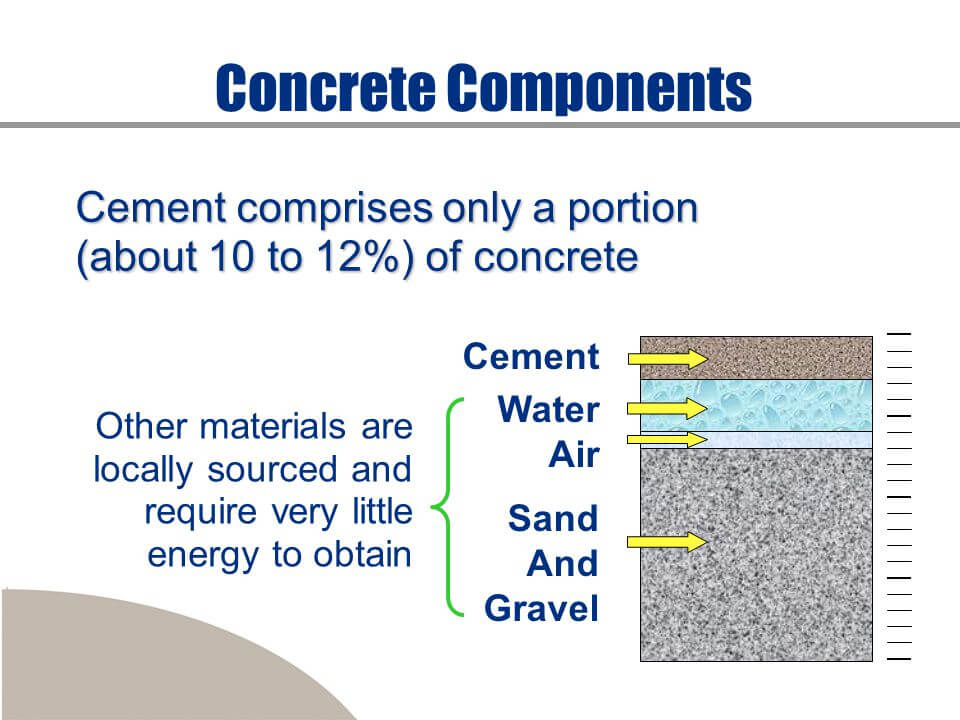

Concrete production is the process of mixing the different ingredients—water, aggregate, cement, and any additives. Modern concrete typically prepares as a viscous fluid, so it should pour into forms, which contains erected within the field to administer the concrete its desired shape.

Read here about How Much Concrete Do I Need?

Batching: Batching is the process of measuring concrete mix ingredients by either mass or volume and introducing them into the mixer. To process concrete material of uniform quality, the ingredients must be measured accurately for every batch.

- Volume Batching

- Weigh Batching

Volume Batching

- This method usually adopts for little jobs.

- Gauge boxes used for measuring the fine and coarse aggregate.

- the amount of the gauge box is adequate the amount of 1 bag of cement.

- they made from timbers or steel.

- Bottomless gauge boxes generally avoided

- Filling the gauge boxes the fabric should filled loosely, no compaction allowed.

Weigh Batching

- Batching by weight is more preferable to volume batching, because it is more accurate and results in more uniform proportioning.

- It doesn’t have uncertainties related to bulking.

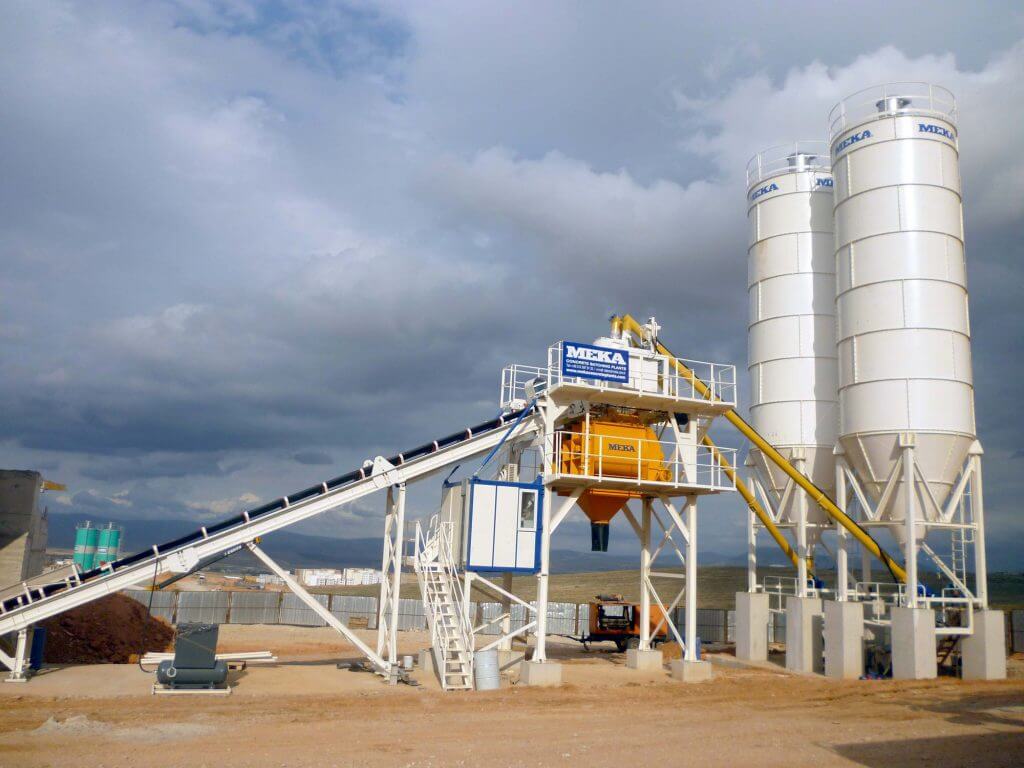

- Its equipment falls into 3 general categories – Manual, Semi-automatic, Fully automatic.

In the case of manual batching, all weighing and batching of concrete done manually. It used for little jobs because semi-automatic, the combination bin gates operated by hand switches and closed automatically when the fabric delivers. It contains interlock which prevents charging and discharging.

In fully automatic, the materials electrically activated by one switch and complete auto graphic record made from a load of every material. The batching plant comprises 2, 3, 4 or 6 compartment bins of several capacities. Over the conveyor, the load batches and discharging provided below the bins.