What is Concrete Pipe?

Concrete pipe in form or another it’s been used for different purposes since the long times of civilization. pipe offers for drainage materials an impressive of performance and strength, making it the most economical and reliable choice today. Recommended installations shallow, moderate or severe cover and live load conditions. Minimize stoppage is the basic shape of Retention.

Uses of Concrete Pipe

Construction of civil field technology made of concrete pipe and a variety of supporting Floating, culverts and precast products. In which steel culverts and pipe, drainage, and water management components are helping to fulfil the infrastructure of needs growing communities in the United States.

- Sewers

- Drains Storm

- Concrete Culverts

- Systems of Irrigation distribution

- Low-pressure sewer force

- Low-pressure water supply

- Treatment piping plant

History of Pipes in America

Pipe have a long history, in sanitary and drainage, sewer systems since the 18th century In America. It’s been using over 6,000 years concrete pipe extensively using had a long history. The performance is best of each pipe are generally function of pipeline. The purpose is to make sanitary storm or sewage water, and together they make a continuous line of concrete pipe with interior joints are designed that when sections laid.

Joints provide soil-tightness with the designed or water, with the ability to longitudinal and deflection, strength, movement and handle shear & vertical movement. Technology advancements in the industry over the last century have led to significant improvements in the pipe manufacturing processes, mix designs, strength, reinforcement, and installation designs. One area that has continued to evolve and progress, along with the rest of the concrete pipe industry, is production and design. pipe offers many types of joints that meet and make strength and standards of performance.

Functions of Pipes

The function of pipeline determines the performance requirements joints of the pipe. When the purpose convey storm or sanitary water, joints designed when sections together, it make continuous line pipe from irregularities with an interior. Pipe Joints designed provide thickness of soil, or water tightness, with ability of accommodate longitudinal or lateral movement strength handle vertical & shear movement.

Read More: What is Concrete Pipe & Its Determination?

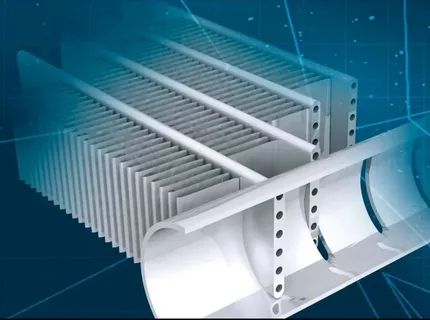

Preparing of RCP Concrete Pipe

Before installing the RC pipe, you have to clean dirt from the surface of the tube carefully. If the surface is appropriately not cleaned, it may cause of failure of the pipe. The deals with the properties and manufacture of a flexible joint of pipe and fitting, reinforced with the steel & unreinforced, it can be used for the conveyance of sewage, and surface water at a pressure of atmospheric.

Because of the elasticity and combined strength of gasket, and because the limited regular space between the concrete surfaces and the socket & spigot is sliding mantle, the intrusion root webs from the trees and plants prevented automatically.

Benefits

Pipe is long live underground piping lines. The saving you wasted and fossils of humans animals and raining weather concrete pipe easy to create a way to dispose of wasted to the exact place where it can needs.