Precast Concrete Blocks

Making of material with Sand, Rivers, and Gravel the getting product it’s called precast concrete blocks. These Blocks have a design decorative blocks colors, and textures. The concrete blocks play an essential role in retaining walls that in designing and manufacturing. Precast blocks have a high level performing retaining wall system. In the New American current climate, and because of their reliability and durability in structure making.

Different Shapes of Blocks

The shape of precast blocks into a 90-degree corner and curved in different designs, which is the helping in the beauty of precast blocks. These blocks use in roads, factories, schools & parks, etc. Creativity and flexibility of precast blocks are fantastic. Concrete blocks an economical solution for the standard application that didn’t require any process of making concrete or mixing and pouring. These are in the form of ready-made high-quality and not expensive at all. Concrete blocks is a product of the construction process by casting concrete; this is a reusable mold.

Making of Concrete Blocks

The form Precast blocks which are cured in controlling the transported & environment, in the construction site and lifted to place. The precast block is distinguished from the precast concrete with using aggregate in mixture, so then the final product approach the appearance naturally getting from rocks or stones. Standard concrete precast blocks are poured into site-specific forms and then bring to the site. There are different types of precast blocks forming system for an architecture application, in sizes, functions, and also cost.

Architectural Precast Blocks

The architectural precast blocks are also used for clad or parts of buildings free-standing and facades for sound-proofing land-scraping, and security purposes, and some pre-stress concrete for the structural element. Storm-water drainage, sewage pipe, water, and the making of tunnels is called precast concrete blocks units. Cement Standard has two colors, grey or white, Depend on what color you want in different colors should add with paints and pigments for the different colors. Aggregate size and color can also affect the texture and appearance of the concrete surface.

Read More: What Makes Concrete Stronger?

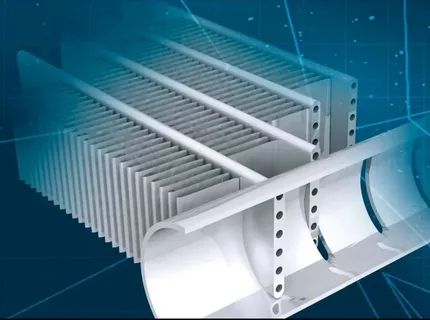

Blocks Surface

The surface and shape of precast blocks have an effected on the look: The blocks can be made by steel, timber, rubber, plastic, or fiberglass; these material gives unique finishing. The strength of precast blocks gradually increases in a short time. Other materials are the experience stress relaxation and creep, resistance, deflected overtimes. And cannot be able to stand vehicular impacts. The load-carried capacity of precast blocks from its structural quality and do not rely on the quality and strength of surrounding backfills material.

Strength of Precast Blocks

The setting of precast concrete structure in place is more comfortable because they don’t require individual rigs to avoid structural damages. Some other materials, like fiber glasses, can suffer structural losses during compactions. In precast concrete blocks is less susceptible to vibratory damages while surrounding soil has bin backfilled. The consequently backfilled operation can usually process much faster to around precast concrete structures. Most of the time, these step or operations help the precast blocks to consistency and long lives strength to structural damages.