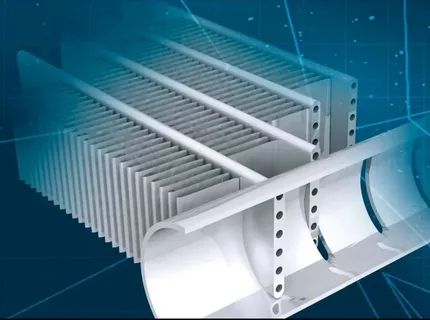

Kaltra manufactures microchannel condense coils that replace traditional three-row copper-aluminum blocks with flat aluminum multi-port tubes. Each tube contains twenty to ninety parallel channels 0.7 mm wide, turning the entire core into a high-performance heat exchanger that rejects identical duty in 45 % less face area while holding internal volume 40 % below conventional coils.

Aluminum fins are louvered at 34° and spaced 18–22 FPI, keeping air-side pressure drop below 65 Pa at 2.5 m s face velocity. Fans therefore absorb 25 % less electrical power over the operating year, cutting kWh and noise simultaneously. Inside the tubes, refrigerant maintains annular flow down to 10 % mass flux, ensuring oil return even during low-ambient startup at −20 °C.

Kaltra vacuum-brazes every joint at 600 °C under nitrogen, creating a monolithic block rated for 30 bar working pressure and 200 °C continuous temperature. The all-aluminum core eliminates galvanic corrosion, giving microchannel condense coils a 20-year design life in coastal or urban atmospheres without protective edge coatings.

Weight drops by 200 kg per 500 kW section, allowing existing roof curbs and rigging chains to remain unchanged. Charge falls from 110 kg to 65 kg on a typical 700 kW chiller, translating into 1 600 € annual carbon-tax savings under current EU levy rates. Lower internal volume also shortens pump-down time during service, cutting maintenance labor by 30 %.

-

Users Save 1 600 €/Year Carbon Tax and One-Day Installation

Headers are CNC-machined to OEM drawing numbers, enabling drop-in replacement without field modification. Integral sub-cooling circuits recover 7 K of liquid temperature, raising chiller COP by 3 % and reducing compressor lift during peak summer afternoons. Fin density is selectable from 18 to 30 FPI, letting engineers balance capacity versus sound power when fans operate at night-time reduced speed.

Kaltra’s sizing portal embeds AI routines trained on 50 000 laboratory tests. Enter heat rejection, air temperature, footprint and refrigerant, and the code returns optimized microchannel condense coils with validated performance curves, fan power and live price within sixty seconds. Export packages include STEP files, wiring diagrams and ERP-ready BOMs, so procurement and service teams work from the same dataset.

Production capacity reaches one million cores per year across plants in Graz and Plzeň, with fourteen vacuum-brazing furnaces operating 24/7. Standard lead time is ten working days; emergency batches ship in 72 hours, pre-brazed, pressure-tested to 52 bar and dried to −40 °C dew point.