Concrete is made of four basic components: coarse aggregate (gravel), fine aggregate (sand), Portland cement, and water. That’s it, but as part of the mixing method, there is also some air, either intentional (entrained air) or just made up in the mixing (entrapped air). All of these elements are mixed then put into place before the cement hydrates and magically the whole thing turns to stone.

Concrete Properties

There are different types of the binding material is used other than cement such as lime for lime and bitumen for asphalt which is used for road construction. It’s technology deals with the research of properties of concrete and its practical applications.

Read about Concrete Material

In building construction, it is used for the construction of foundations, columns, beams, slabs and other load-bearing details. There are different types of the binding material is used other than cement such as lime for lime and bitumen for asphalt which is used for road construction.

There are many types of concrete but we have covered the basic and most important concretes;

Types of Concrete

1. Plain/Ordinary

In this type, the essential ingredients are cement, sand and coarse aggregates designed, and mixed with a specified amount of water.

The proportion of essential ingredients may be varied within broad limits. A very commonly used mix design, commonly known as Nominal Mix Design. Plain concrete is mostly used in the construction of pavements and in buildings, where very high tensile strength is not required. It is also used in the construction of Dams.

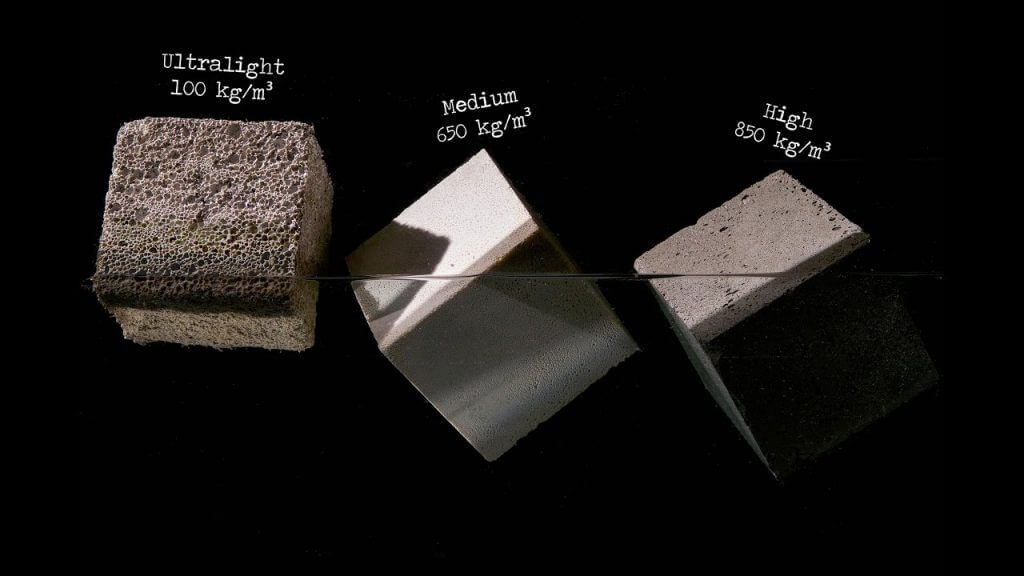

2. Lightweight

Any types of concrete having a weight less than 1920 Kg/m3 is classed as lightweight.

Various types of aggregates that are applied in the manufacturing of lightweight concrete include natural elements like pumice and Scotia, artificial materials like expanded shale and clay and processed materials like per-lite and vermiculite. The single important lot of this is, its very low thermal conductivity.

3. High-density

This type is also called heavyweight concrete. In this type, the weight r thickness varies between 3000-4000 Kg/m3. These are made by using high density crushed rocks as coarse aggregates. Among such materials, Barytes is the most commonly used material, which has a specific gravity of 4.5.

They are mostly used in atomic power plants and other related structures because it provides excellent protection from all type of radiations.

4. Reinforced

It is also called RCC (Reinforced Cement Concrete). In this type, steel in many forms is used as reinforcement to give very high tensile strength.

It is because of the mixed r merged action of plain concrete (having high compressive strength) and steel (having high tensile strength). The steel reinforcement is counted in the form of rods, bars, meshes, and all conceivable shapes.

5. Precast

This term refers to various types of concrete shapes that are cast into molds either in a factory or at the site. However, they are not practiced in construction until they fully set and hardened in a controlled condition.