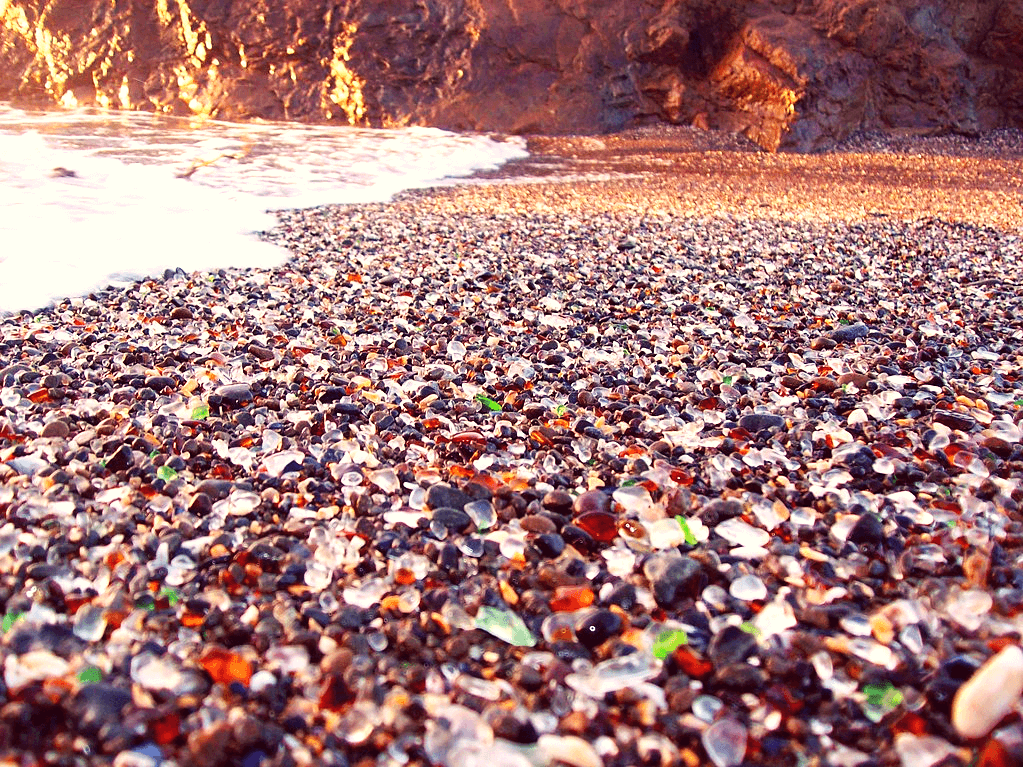

The glass aggregate used for decoration of concrete structure floors, patio, entrance, etc. Too making structure beautiful and furnish and suitable for rest of houses and residential homes, offices, schools, banks, etc.

Glass aggregate replaces the gravel and sand in concrete, for effects ranging from colorful marble or granite for finishes, to the concrete are the reflected light like a mirror.

Uses of Glass Aggregates

The applications of glass aggregates as special aggregates for decorative concrete is increases to making more color improvement & decorative purposes.

Making with alkali-silica private hands with gravels & sand mixture. The best thing about glass aggregates.

Making of Glass Aggregates

Glass aggregate concrete consists of sand aggregates and different sizes and shapes of the gravel or stones & coarse aggregate. However, there is a vast growing interest in the alternatives aggregate materials, generically as a likely used to recycle materials.

There is Momentous research on the different materials for aggregate surrogate such as granulated blast furnace slag, coal ash, or different solid wasted including waste material of fiberglass, plastics, and paper, wood or, sintered sludge pellets and others.

The waste glass was use in the ideal and coarse aggregates replacement in concrete. The ratio of Glass aggregates 99% replacement with Green Bottles of coarse aggregates at two thirds (1:2:3) or third. The concrete mix design replacement with a third coarse aggregate that was the most suitable for retaining materials for the properties. An excellent total, to account the number of variables & established top of a benchmark, were used in parameters like sand grading, color glass, waste glass & mix design strength.

Fine aggregates used in making colorful glass aggregates like transparent bottles brown and green gives structure finishing to use Glass.

Concrete aggregates properties were tested to harden and current states. The incorporate glass sand and the regardless of ratio to replacement shows that is no significant influences on the mechanical and bright property of concrete for the case in transparent bottles.

Making with wasted material of aggregates

Glass aggregates produced with waste in considerable annually amounts of lost in garbage. Due to the disadvantages of nature of its recycling process, it’s introduced the importance and proves that can make the best aggregates with that staff.

High reactivity levels of the glass incorporation mixture, that the reused waste glass as aggregate in polymer structure of concrete that can use. Size of wasted Glass aggregates 6 to 8 mm, used in floors, walls, etc.

Read More: How much does it cost to Stencil Concrete?

Lightweight Aggregates

The thin glass aggregates get from a natural resource, and it can also be made by hand or machinery. The most significant natural resource for sums is ‘volcanic.’ With the help of volcanic materials, we can produce synthetic aggregates.

These aggregate are used in the way of thermal treatment for the expansive properties. There are plenty of other materials that can be divided into the three groups like perlite, vermiculite, natural materials, clay, slate, and shale in industrial products like Glass & fabric such as fly ash, slag coal, and bed ashes.